What is Calcining?

Calcining is the process of heating a powder or solid material to high temperatures (typically over 500 °C) to remove residual moisture, volatile components or initiate chemical transformation in a controlled thermal treatment.

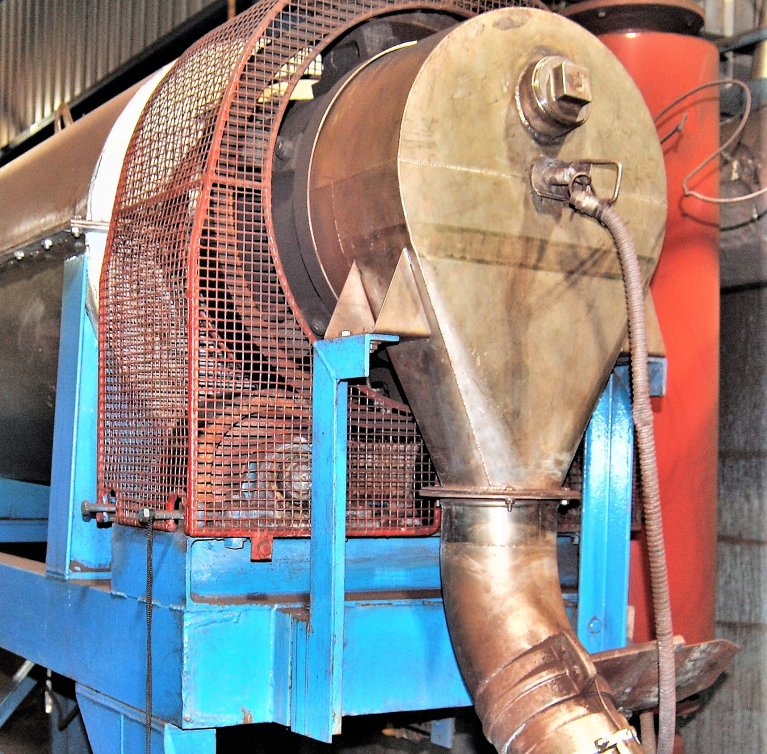

Our Calcining Facility

Typical Uses & Applications

Calcining is particularly useful for drying powders or solids derived from slurries, removing moisture after synthesis, or preparing materials (e.g. salts, catalysts or specialty inorganic powders) for further thermal or chemical processing. The treatment can also induce phase changes or decomposition, depending on the material and intended application.

-500-width.jpg)

Enquiry Form

Enquiry Form Chemical Listing

Chemical Listing