Tannin, also called tannic acid, can be any of a group of pale-yellow to light-brown unstructured substances in the form of powder, flakes, or a spongy mass and widely distributed in plants. They are predominately utilised in

• tanning leather

• dyeing fabric

• making ink

• various medical applications

Tannin solutions are acid and have a bitter taste. Tannin is responsible for the astringency, colour, and some of the flavour in tea.

Tannins occur normally in the roots, wood, bark, leaves, and fruit of many plants, particularly in the bark of oak species and in sumac and myrobalan.

In addition to their principal applications in leather manufacture and dyeing, tannins are used in

• In the clarification of wine and beer

• as an ingredient to reduce viscosity of drilling mud for oil wells

• in boiler water to prevent scale formation

Soluble in water, tannins form dark blue or dark green solutions with iron salts, a property utilized in the manufacture of ink.

Tannins may be classified chemically into two main groups

• Hydrolysable

• Condensed

Hydrolysable tannins (decomposable in water, with which they react to form other substances), yield various water-soluble products, such as gallic acid and protocatechuic acid and sugars. Gallotannin, or common tannic acid, is the best known of the hydrolysable tannins. It is produced by extraction with water or organic solvents from Turkish or Chinese nutgall. Tara, the pod from Caesalpinia spinosa, a plant native to Peru, contains a gallotannin similar to that from galls and has become an important source for refined tannin and gallic acid. The European chestnut tree (principally Castanea sativa) and the American chestnut oak (Quercus prinus) yield hydrolyzable tannins important in leather manufacture.

Condensed tannins, the larger group, form insoluble precipitates called tanner’s reds, or phlobaphenes. Among the important condensed tannins are the extracts from the wood or bark of quebracho, mangrove, and wattle.

History

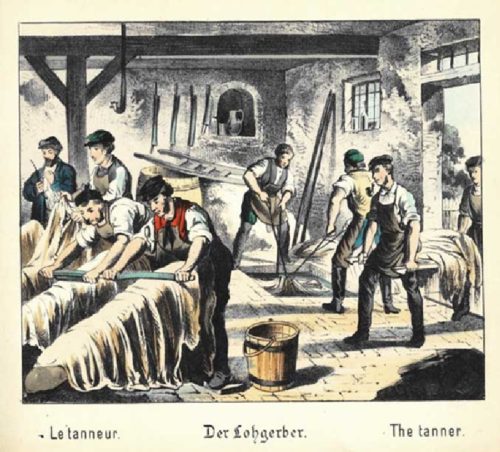

Vegetable tanning is a traditional craft process that tanneries have handed down from father to son for over 200 years, using both ancient recipes and state-of-the-art technology. With vegetable tanned products, you can really see the skill that has gone into producing them.

The transformation from raw hides into a material that will last a long time is a process that happens slowly in wooden drums while respecting the environment. It is an astonishing process based on the use of natural tannins, on modern technologies and machinery but mainly, on the slow passage of time.

Among the various tanning methods, the vegetable tanning is the most classical, the most traditional, the most recognizable, the only one able to give leather unique characteristics, the most natural and the most environmentally-friendly. It is able to join comfort and look, fashion and tradition, uniqueness and versatility in the product.

High-quality vegetable tanning is disappearing in Europe, with an exception of Italy, where Consortium is the world-beaters of the tradition, handcraft, and innovation in fashion.

Genuine Italian Vegetable-Tanned Leather Consortium promotes the concept of natural vegetable tanning and to keep the Italian vegetable tanning tradition alive.

The Tanning Process

Before tanning the hair or wool is removed from the pelt, usually by the application of selected chemicals to eat away at the hair roots. Treatment with lime is done to open up the fibres and remove unwanted material from between the fibres. Other processes will be carried out to specifically remove any hair roots and adjust the stretch characteristics and some physical processes will remove the flesh and thicker hides will be split to get to the correct thickness.

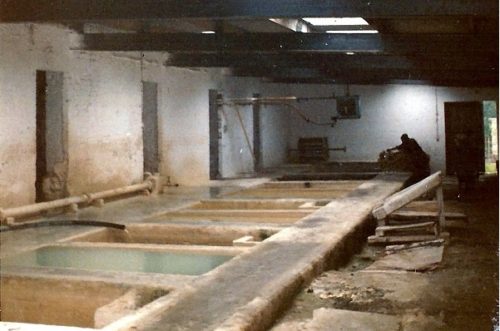

Historically vegetable tanning was done in a series of pits with different concentrations of tannins. Today many tanners make fine leather using systems of drums and pits and some work with drums alone, which can greatly reduce the time involved as the drum action speeds the penetration of the tan into the leather.

Tanning starts with a penetration process leaving the combination (with the hide) until the tan is well through the leather. The first tan to reach the leather must be weak in concentration and mellow to prevent tanning the surface early on. So a setup is created that moves from a low tan:non tan ratio to a high tan: non tan ratio.

With pits a counter current system is normal where the hides move through a series of pits in one direction while the liquors move the other way. The hides go through three sets of pits which are the Suspenders, the Handlers and finally the Layers (cold method) or the Hot Pits (more common today).

In the layers each hide is sprinkled with solid tan material. Fermentation and deposition in the hide gives solid leather in 3 months. Traditional oak bark leather is required to be in the tan pits for a minimum of one year. The strong liquors from the final pits are gradually moved down the system while the hides move up from weak to strong. At the end the leather is piled for a few days to completely fix the tan.

Once Tanned

After tanning many varied processes follow which are often classified as Currying or Shedding vegetable tanned leather. Activity may involve treating the leather so the veg tan does not migrate to the surface, rolling on when the leather is quite moist, rolling off when it is a little drier. Drying is done in a stove, with the hides or skins usually hanging from hooks. Wooden slatted windows may be used to crudely adjust temperature and provide ventilation.

Vegetable Tannins

• The Quebracho, coming from the Spanish words “quiebra hacha” (“break the axe” because of its hardness) is obtained from the inner red core of a hardwood tree which grows only in a specific part of North Argentina in a limited region close to the border with Brazil and Paraguay.

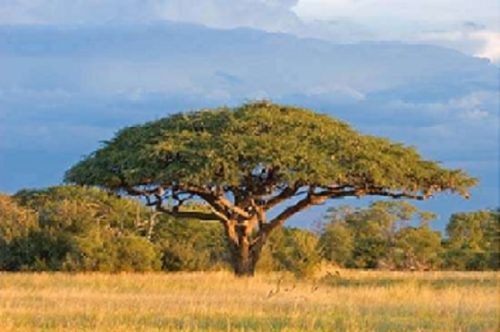

• The Mimosa tanning extract is derived from the bark of a Black Wattle tree. This is a tree similar to the one which grows in our gardens and has the highest concentration of tannin in its bark.

• The Chestnut extract comes from the wood of the Mediterranean typical tree and is the third most important vegetable tannin for leather production.

The features of tannins are unique and inimitable, fortunately they cannot be replaced by synthetics during leather manufacturing processes.

Tannins are not used only for tanning industry but also in the following fields:

• for animal feed

• in wine industry

• for wood chipboard

• for corrugated cardboard

• as auxiliaries for wastewater treatment

• for anti-rust and rust converter products

• as an accessory for drilling oil wells

• as floating agents in mineral treatment processes

Advantages of Vegetable Tanning

• Vegetable tanning is environmentally friendly; meaning any leather products that have been vegetable tanned can be recycled.

• Vegetable tanning is an age-old tradition, so most tanneries have very skilled craftsmen producing and dyeing the leather.

• Due to the natural tannins used, vegetable tanned products are unique and have their own life, they are not the same for their entire life, but they change, continuously, for the better.

• The colours that vegetable tanning produces are rich and warm tones that look completely natural.

• Vegetable tanned leathers are more valuable and sold at a higher average price compared to chrome tanned leathers.

Disadvantages of Vegetable Tanning

• The average process time of vegetable tanning is quite similar to chrome tanned leather but it can take up to 60 days to produce sole leather.

• It can stain easily in the presence of iron.

• Products that have been vegetable tanned are more expensive. They require much more skill to tan the hides, this means they are of better quality.

• The colours you can produce from vegetable tanning are limited.

• Direct heat can cause vegetable tanned products to shrink or crack.

Tannin Extracts for Industrial Applications

When companies have experience and knowledge in the production of vegetable extracts, it possible to develop a wide range of products suitable for specific industrial applications:

• Fireproofing wood

• Industrial lubrication

• Mining

• Oil drilling

• Sewage treatment

• Textiles

The Benefits of Tannin to Steam Boilers

Tannin has proven itself to be highly effective against oxygen corrosion due to its nature as an oxygen scavenger, by removing the oxygen from the boiler. Due to this, feed tank corrosion cannot set in prolonging the life of the boiler substantially. Additionally, Tannin will form a thin corrosion resistant tannate film across the boiler surface. Even when the boiler is not in service and has cooled down, the dosing of Tannin is still important as its effectiveness is not influenced by temperature.

For more information on these products click on Mimosa or Quebracho or to discuss your requirements please contact us on 01283 792600 or email sales@platerchemicals.co.uk

-500-width.jpg)