In line with the company’s Environmental Standard ISO14001, Plater Group have shown they operate the systematic framework by which they manage the environmental impacts of their products, services and processes.

The company, committed to reducing their impact on the environment as a sustainable business, are delighted to report the success of the launch of two energy saving initiatives to significantly reduce their energy usage.

In 2018 Plater Group embarked on these projects not only to significantly reduce their energy consumption but to also provide long term sustainability for site service requirements.

This takes the form of providing steam and compressed air for the Glossop site.

Compressed air

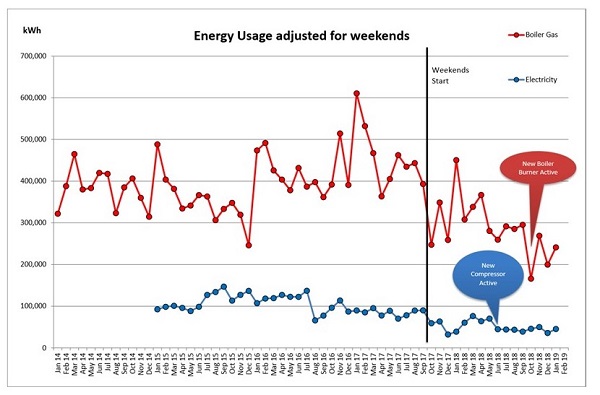

In May 2018, the company installed 2 new compressors to provide compressed air for the site. Prior to this a compressor manufactured in 1992 did the job, however the technology involved in compressing air has moved on significantly since then and it is now possible to do this much more efficiently using less electricity.

Since their installation in May, the new compressors are saving an average of £5,000 electricity costs per month for the site.

Steam Generation

In October 2018, the company installed a new burner in the site steam boiler to produce steam for the Glossop site. Prior to this, the boiler used a burner that was installed in 1976. The boiler was inspected and shown to be in really good condition, however it was fitted with an inefficient gas burner.

The problem with the burner is that it only operated by being ‘on’ or ‘off’. Every time the burner needed to come ‘on’, it went through an inefficient purge cycle that cooled the boiler down, before igniting and heating to then produce steam again. The new burner is a modulating burner that can turn itself down very low and thus avoid the inefficient purge cycle.

Since October, the new boiler burner is saving an average of £4,000 gas costs per month for the site.

To view our ISO14001 accreditation, please click here, or to discover more about our environmental initiatives, please contact us

-500-width.jpg)