No-till cultivation involves preventing/minimising soil disturbance by eliminating ploughing and drilling seeds directly into the seed bed left by the previous crop. Once considered the preserve of hippies by mainstream agriculture, no-till agriculture has now gained widespread acceptance in the US and Europe. This acceptance is down to farmers appreciating the less intense nature of no-till farming, which translates into lower operational costs and long-term improvements to soil structure with associated environmental benefits. However, greater acceptance of no-till cultivation requires there to be solutions to some of the remaining challenges for the practise that has limited its acceptance and prevented maximum yields. These three key challenges are:

Challenge 1: Dealing with the crop residue (stubble) left over from the previous crop;

Challenge 2: Ensuring adequate aeration/drainage without the need for ploughing; and

Challenge 3: Weed control; in the UK this is particularly important for black grass (Alopecurus myosuroides), barren brome (Bromus sterilis), and couch grass.

These challenges are estimated by the UK Agriculture and Horticulture Development Board to be the key factors limiting yield in no-till cereal crops. In order to overcome these challenges Plater Bio have developed a number of innovative new products that are targeted at no-till cultivation. They are all compatible with current practices and address the three challenges directly.

Challenge 1: Dealing with crop residues

The in-house carboxylic acid technology in Plater Bio’s Stubble Digester stimulates the native saprotrophic fungi already in the soil to speed up the breakdown of crop residues that remain after a crop is harvested. This acceleration of the nutrient cycling process improves nutrient availability and helps prevent practical problems with the stubble interfering with the seed drills. Residual stubble has also been found to delay germination, be a source of fungal toxins and a food source for slugs. Unlike microbial products targeted at stubble that ‘seed’ the field with the spores of saprotrophic fungi, Plater Bio’s Stubble Digestor is more consistent at breaking down crop residues as it stimulates the natural saprotrophic fungi that already inhabit the soil. We have already seen great results from the technology in Stubble Digestor at stimulating saprotrophic fungi in horticultural settings, and will expand these trials to no-till arable fields in Q3 2017.

In addition to releasing the nutrients locked up in the organic matter, nutrient cycling/efficiency will be further improved in no-till fields by the use of Phosphorus Liberator which helps solubilizes locked phosphorus in the soil. It is well-known that agricultural soils are not lacking in phosphorus, it is just a case of availability. As such, releasing bound phosphorus in no-till fields is often a better solution than adding even more to the soil as fertilizer, which is known to be toxic/deleterious to the mycorrhizal fungi which we are trying to stimulate and cultivate in no-till soils.

Challenge 2: Ensuring adequate aeration/drainage

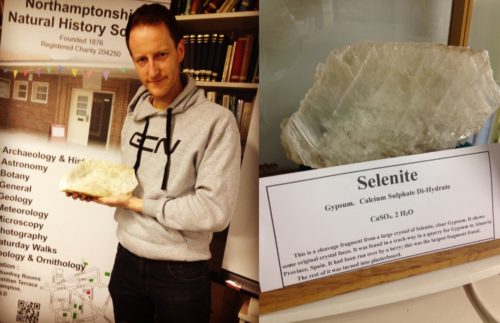

Gypsum is a well-known soil flocculant that is used in all types of agriculture to aid the formulation of a crumb structure that is optimal for drainage and aeration. In conventional agriculture, the fact that granular gypsum (pictured below) is only very mildly soluble is not an issue as it will be worked into the top soil horizon during ploughing. However, in no-till cultivation granular gypsum and liquid suspensions made from granular gypsum will only be effective at treating the very top of the top ‘O’ horizon and not penetrate into the top soil (B horizon). In contrast Plater Bio Liquid Gypsum is a solution and thus able to penetrate the entire top soil and flocculate at depths where the crop’s roots will be most active. Liquid Gypsum is also x 2,000 more effective than granular gypsum meaning flocculation will occur at the time of application. Plater Bio will be running a series of percolation tests in Q3 2017 to determine the effectiveness of Liquid Gypsum at increasing and improving the drainage of waterlogged arable fields.

In addition to its flocculating effect, gypsum is also a good source of calcium and sulphur. Deficiencies in sulphur are now more common in the UK as atmospheric SO2 levels have dropped due to reduced air pollution from heavy industry. For oil seed rape this is particularly important as the glucosinolates they produce to resist pests and diseases are sulphur-containing. Calcium is also a key macronutrient that is known to affect crop resilience due to its importance in maintaining healthy cell walls and membranes. Without adequate calcium plants will be more susceptible to environmental stress and attack by pests and disease.

While Lime Sulphur is another potential liquid flocculant for no-till cultivate, it is extremely toxic to the beneficial soil microbiome and is far more expensive.

Plater Bio are also Europe’s only producer of fungal chitosan, another powerful flocculant. Fungal chitosan is not hazardous to health or to the environment and is organic. However, chitosan is best used as a biopesticide. As many no-till farmers are also organic farmers, they should also consider chitosan biopesticide treatments. Since 2014 chitosan can be used under EU ‘basic substance’ organic regulations for the control of fungi and bacterial diseases and can be applied as a foliar spraying or seed coating. While popular in Southern Europe, farmers in Britain have yet to adopt the technology. We are currently planning trials to assess chitosan’s efficacy on a range of pests and diseases on cereals and rape crops in the UK.

Challenge 3: Weed control

As black grass is known to thrive in wet and waterlogged soils we are hoping to assess the long-term impact on liquid gypsum on part of an IPM programme to control this pernicious weed.

Other useful products for no-till include treatments that will stimulate the beneficial soil microbial community (microbiome). This includes seaweed extracts, humates, sugars and amino acids. However, be careful not to add too much in order to prevent anaerobic conditions being generated in the top soil horizon. Some biological farming consultants will also encourage farmers to use humates to cure a whole host of other ills, but humates are not a panacea. Instead humates should be viewed as essentially a substitute for insufficient soluble humus in the soil, and as such are great treatments for sandy soils early into a conversion program for example. However, the major characteristic of a no-till soil is an abundance of organic matter, not a lack of it (see University of Wisconsin video for more details). Furthermore, any claims that humate products will improve soil drainage or chelate micronutrients have little scientific basis.

If you would like more information on the products and concepts mentioned in this post please contact me. I will also be attending the No-till Conference “Groundswell” in Hertfordshire on 29th June 2017 and would happy to meet up to discuss.

-500-width.jpg)